The Weekly Potential #12

This week in the energy and materials industries: Northvolt’s troubles, recycling semiconductors into silicon anodes, Honda’s solid-state dreams, EU-China tech confrontations, -40°C NIBs, ...

Welcome to the 12th edition of The Weekly Potential, a newsletter providing you insights into the energy and materials industries. This week we are diving into Northvolt’s troubles, recycling semiconductors into silicon anodes, Honda’s solid-state dreams, EU-China tech confrontations, -40°C sodium-ion batteries, 50 MWh BESS made with second-life batteries, and more.

Let's dive in! 🔋

Lithium Horizons is a reader-supported publication. For deeper insights, including in-depth analysis, the latest developments, and expert insights into the energy and materials industries, subscribe below.

Industry Developments

NEO Battery Materials has joined a $20 million project focused on recycling silicon from semiconductor and photovoltaic wafer manufacturing into high-performance silicon anode materials. This initiative, titled "Recycled Silicon-Based High Energy Density Electrode Manufacturing Technology Development" is led by the South Korean Ministry of Trade, Industry, and Energy and involves key industry players such as Hansol Chemical, INNOX eco-M, and LiBEST. The five-year project aims to enhance sustainability in the lithium-ion battery sector by converting waste into valuable components for electric vehicle batteries.

Honda Motor Co., Ltd. has announced the completion of a demonstration production line for its all-solid-state batteries at the R&D facility in Sakura City, Japan. This line spans about 27,400 square meters and will be used to test the production of Honda’s all-solid-state batteries that could double the electric vehicle driving range by 2030. Honda is aiming to reduce battery size by 50%, weight by 35% and costs by 25% within five years.

LG Chem and ExxonMobil have signed a non-binding Memorandum of Understanding for a multiyear offtake agreement, where ExxonMobil will supply up to 100,000 metric tons of lithium carbonate from its planned U.S. project to LG Chem's cathode plant in Tennessee. The lithium will be produced using Direct Lithium Extraction (DLE) technology, which promises a lower environmental impact compared to traditional mining methods.

Northvolt has filed for Chapter 11 bankruptcy in the United States due to significant financial strain, with debts amounting to approximately $5.8 billion. The company faced several challenges including production delays, the loss of a major contract with BMW, and an inability to secure rescue funding, leaving it with only one week's worth of cash reserves. This filing will allow Northvolt to restructure its finances, scale back operations, and access approximately $245 million in new financing

The European Union is planning to enforce technology transfers from Chinese companies in exchange for EU subsidies. This policy will apply to batteries initially but could be expanded to other green sectors. It will initially target a €1 billion battery grant scheme in December 2024, mirroring the practices China has long applied to foreign firms seeking market access. The new criteria demand that Chinese businesses not only share technological know-how but also establish manufacturing facilities within Europe.

CATL has announced its second-generation sodium-ion battery technology capable of operating even in temperatures as low as -40°C. This advancement addresses one of the critical drawbacks of traditional lithium-ion batteries, which experience reduced performance in extreme cold. Although specific energy density figures haven't been disclosed, there are indications that CATL aims for these batteries to exceed 200 Wh/kg, aligning them closer to lithium-ion in terms of energy storage capacity.

Element Energy has commissioned what it claims to be the world's largest second-life battery energy storage system (BESS) with a capacity of 53MWh in Texas. This project utilizes repurposed electric vehicle batteries to contributes to electric grid stability by storing and supplying electricity from renewable sources during peak demand times.

Paper of the Week

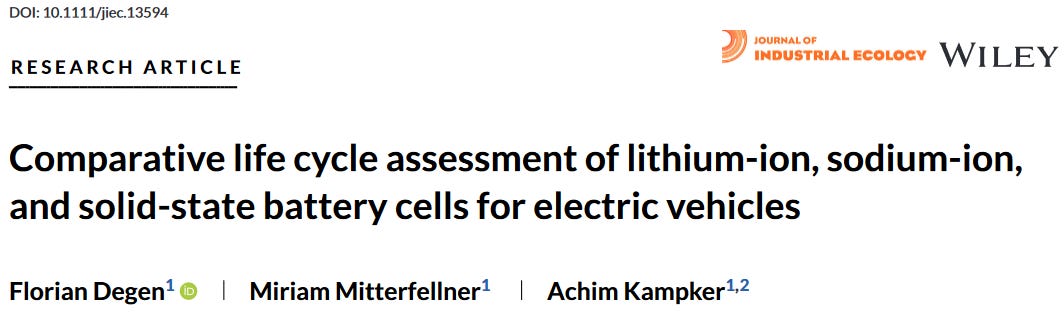

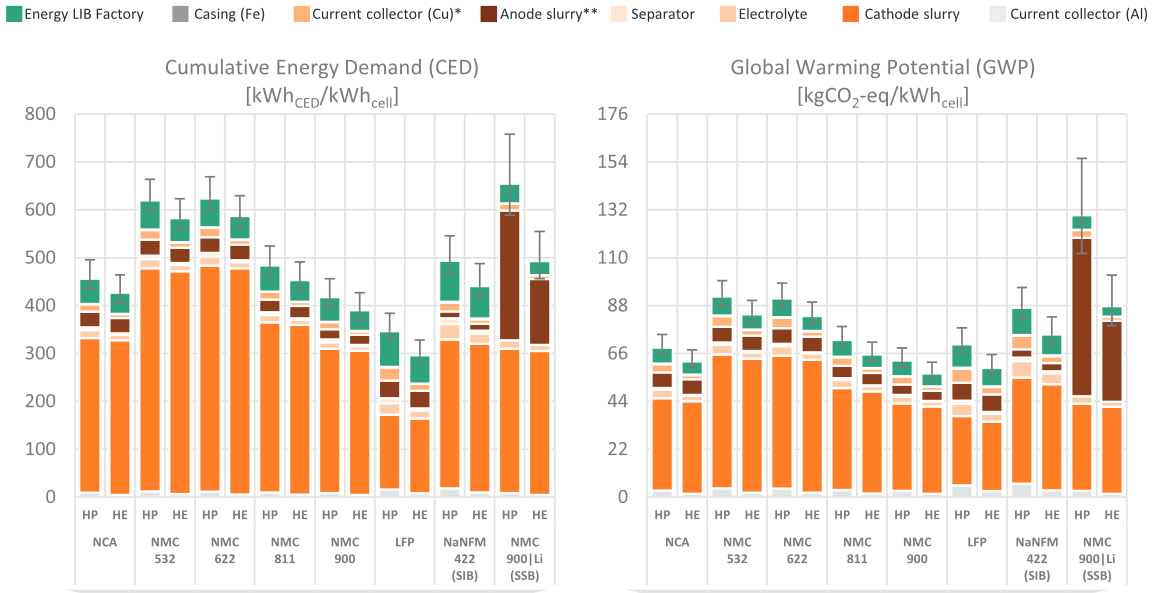

The Journal of Industrial Ecology has published an article examining the lifecycle impacts of lithium-ion, sodium-ion, and solid-state battery cells used in electric vehicles. According to the life cycle assessment, the production of lithium-ion battery cells currently emits approximately 58–92 kg CO2-eq per kWh of cell, with an energy input ranging from 296–624 kWh per kWh of cell produced. For sodium-ion battery cell production, emissions are slightly higher at 75–87 kg CO2-eq per kWh. Solid-state batteries, on the other hand, emit between 88–130 kg CO2-eq per kWh. The study suggests that lithium iron phosphate (LFP) cells have the lowest energy input among the three, while a solid-state Li-NMC900 battery emerges as the most environmentally sustainable option.

On the Go

Battery Insiders Podcast talked to Celina Mikolajczak, Chief Battery Technology Officer at Lyten, to discuss lithium-sulfur technology as a promising alternative to lithium-ion, offering cost efficiency, scalability, and a reduced carbon footprint.

Read More

Thank you for reading. If you found the post interesting, consider sharing it with your network and subscribing. Such actions help spread the knowledge and support Lithium Horizons.