The Weekly Potential #19: Battery Insights

This week in the battery industry: CATL's slowing profits, Northvolt bankruptcy, Tesla's expansions, BYD's 1000V architecture, EU's €1.8 billion investment, CALB's Portugal factory, ...

Welcome to the 19th edition of The Weekly Potential, your premier source for insights into the battery industry.

This week, we focus on the European Union's efforts to catch up in the global battery race. The industry is undergoing a significant shift as Chinese LFP cells become commoditized amid stiffening competition, redirecting attention to Europe's struggling battery sector.

The recent bankruptcy of Northvolt, a once promising Swedish battery manufacturer, has sent shockwaves through the industry. As Europe grapples with this setback, Chinese battery giants and Tesla are seizing the opportunity to expand their footprint.

Let's dive in! 🔋

Lithium Horizons is a reader-supported publication. For deeper insights, including in-depth analysis, the latest developments, and expert insights into the battery, energy, and materials industries, subscribe below.

Ten Key Industry Developments

CATL, the world’s leading EV battery maker, recorded its slowest profit growth in six years in 2024, with net profit rising 15% to $7 billion, fueled by declining lithium prices and a price war in China’s EV market. CATL batteries for energy storage systems grew the fastest, making up 22% of total shipments. Retaining a 38% global market share, CATL is planning a $5 billion Hong Kong listing to finance expansion, including a new factory in Hungary. (Read more)

Cornish Lithium has gained approval on March 14, 2025, to construct the UK’s first commercial geothermal lithium facility in Cornwall, using Direct Lithium Extraction from geothermal waters. The project, starting with two 2,000-meter deep wells, aims to reduce UK reliance on imported lithium for EV batteries while exploring local geothermal heat use. (Read more)

Rendering of the Cornish Lithium’s geothermal lithium facility. Source: Think Geoenergy Northvolt, a prominent Swedish EV battery manufacturer, filed for bankruptcy in Sweden on March 12, 2025. Once valued at $12 billion, the company faced mounting debts exceeding $5.8 billion and dwindling cash reserves, prompting the filing after failing to secure a rescue package. This collapse jeopardizes 5,000 jobs and raises doubts about its planned $7 billion Quebec plant. (Read more)

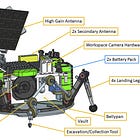

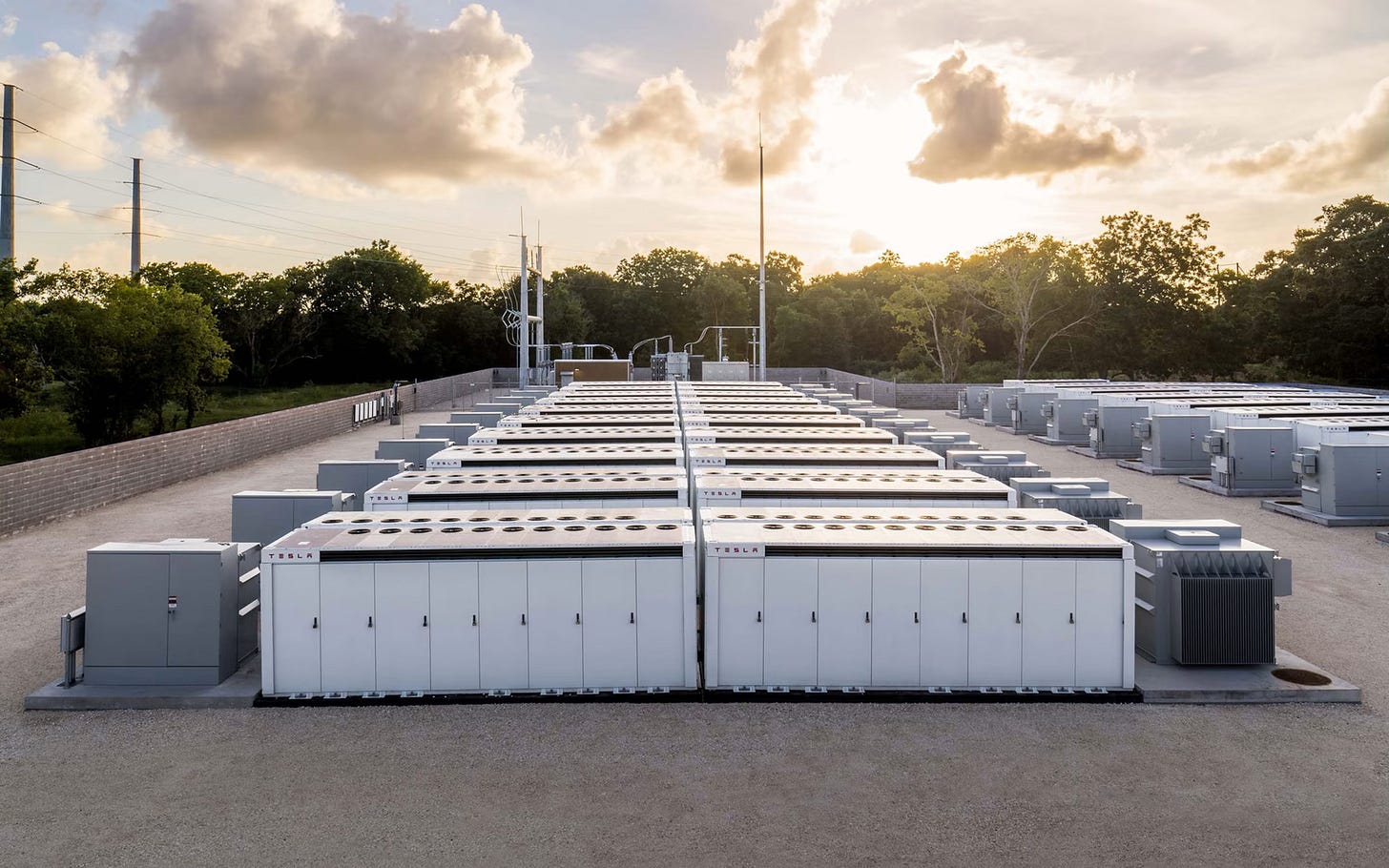

Tesla is expanding its Megapack production with a new facility in Waller County, Texas. The company will repurpose a 1.6-million-square-foot site near Houston, investing nearly $200 million in upgrades and equipment, aiming to create 1,500 jobs and generate $8-10 billion in annual revenue. This move bolsters Tesla’s energy storage business amid growing demand for grid-scale solutions. (Read more)

Tesla Megapack BESS installation. Source: Tesla Porsche has secured a majority stake in Varta’s V4Drive battery unit. The German sports car maker invested €30 million to bolster Varta’s restructuring, gaining access to high-performance lithium-ion cells for its hybrid and electric vehicles, while Varta retains a minority stake. This strategic move enhances Porsche’s control over its battery supply chain amid a shifting EV landscape. (Read more)

BYD, a leading Chinese EV manufacturer, is set to introduce its 1000V electric vehicle architecture on March 17, 2025, promising ultra-fast 5C charging capabilities. The technology, debuting with the Han L and Tang L models, aims to deliver 300 km of range in just five minutes, supported by a nationwide rollout of 1000V-compatible superchargers in collaboration with Sinopec. (Read more)

BYD Han L electric vehicle. Source: Car News China The European Union has committed €1.8 billion to strengthen its automotive industry, with the funding announced on March 10, 2025, by the European Commission. This investment targets securing supply chains for battery raw materials, aiming to boost Europe’s EV battery production and reduce reliance on imports amid rising global competition. The initiative supports the EU’s green transition goals and resilience in the automotive sector. (Read more)

Volklec, a UK-based battery startup, has partnered with China’s Far East Battery (FEB) to produce advanced lithium-ion batteries using licensed technology, with production starting at the UK Battery Industrialisation Centre in Coventry by late 2025. The agreement aims for a 1 GWh power cell line by 2026 and a £1 billion, 10 GWh gigafactory by 2030. (Read more)

Rendering of a Volklec 21700 battery cell. Source: Volklec Tesla has bolstered its automation capabilities by acquiring key assets from insolvent German firm Manz AG. Through its subsidiary Tesla Automation GmbH, the company will take over the Reutlingen site, including over 300 employees and advanced machinery, enhancing its production efficiency for electric vehicles and batteries. (Read more)

CALB, a Chinese battery manufacturer, broke ground on its first European factory in Sines, Portugal, on February 24, 2025, with a €2 billion investment. The gigafactory, set to begin production in 2027, will produce lithium-ion batteries for EVs and energy storage with an initial capacity of 15 GWh, creating 1,800 jobs and boosting Portugal’s role in Europe’s green energy transition. (Read more)

Paper of the Week

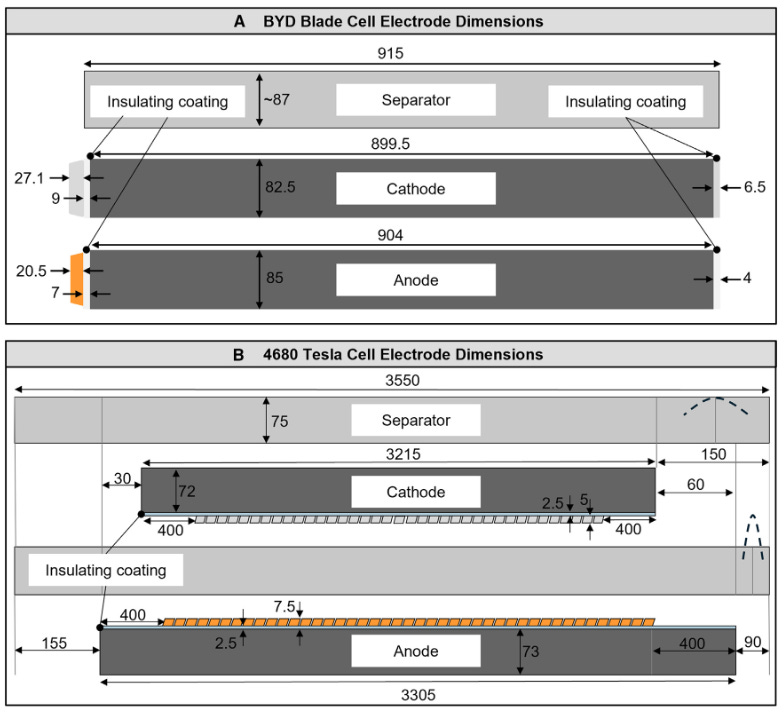

Researchers from RWTH Aachen University have published a paper comparing BYD's Blade prismatic cell with Tesla's 4680 cylindrical cell. Although the comparison is not directly equivalent, as both the formats and chemistries of the cells differ, the paper offers a rare glimpse into BYD and Tesla cell designs.

The study reveals that Tesla's 4680 cell prioritizes high energy density, using a cylindrical shape and NMC811 cathode chemistry. It achieves a gravimetric energy density of 241 Wh/kg and a volumetric energy density of 643.3 Wh/L. In contrast, BYD's Blade cell focuses on safety, longevity, and cost-effectiveness, employing a prismatic format and LFP chemistry. The Blade cell has a lower energy of 160 Wh/kg gravimetrically and 355 Wh/L volumetrically.

The research also highlights significant differences in thermal management, with Tesla's 4680 cell generating about twice as much heat as the BYD Blade cell at the same C-rate. This necessitates more robust cooling systems for Tesla's batteries. BYD's approach allows for simpler thermal management, making the Blade cell more efficient in this aspect.

On the Go

Ken Davies sat down with Ryan Spray, Principal Scientist at Exponent, to explore thermal safety in batteries. As battery packs become larger and more energy-dense, the importance of effective thermal safety management grows. This conversation highlights the challenges and solutions in maintaining thermal stability, which is crucial for preventing overheating and ensuring the longevity and performance of batteries.

Read More

Thank you for reading! We appreciate your engagement and invite you to subscribe for more updates. Please share your thoughts and feedback in the comments below. If there's a specific topic you'd like us to explore in future editions, feel free to let us know in the comments. Your input helps us tailor our content to better meet your interests.